Symposium “Third Generation Advanced High Strength Steels by Quenching and Partitioning”, MSE 2016 Congress

The Symposium ‘Third generation advanced high strength steels by quenching and partitioning’ organized by the OptiQPAP consortium members was held in frame of the MSE 2016 Congress (Darmstadt, Germany) on September 27. The main objective of this Symposium was to disseminate the recent developments in the application and modelling of quenching and partitioning heat treatment to production of third generation advanced high strength steels and to facilitate a more intense development in this field of research. The Symposium has attracted a significant interest of both steel industry and academia, and favored networking and international collaboration in this exciting field of science and technology. The keynote and invited talks were given by researchers from the world largest steel manufacturing companies and Colorado School of Mines (USA). Dr. Stefan Van Bohemen (Tata Steel, The Netherlands) presented his key-note talk on annealing strategies for fabrication of ultra-high strength steels with enhanced formability. Prof. Emmanuel De Moor (Colorado School of Mines, USA) devoted his talk to chemistry design in Q&P steels with special emphasis on Mn. The lecture by Dr. Dorien De Knijf (Arcelor Mittal Gent, Belgium) was focused on Nb and Nb+Mo alloying of Q&P steels to improve their properties. The effect of Si on microstructure and mechanical properties of press hardening steels subjected to Q&P treatment was considered in the talk of Bernd Linke (ThyssenKrupp AG, Germany). Dr. Irene De Diego Calderon (Arcelor Mittal Metz, France) discussed the microstructure – fatigue properties relationship in Q&P treated steels and mechanisms governing their fatigue behavior. Dr. Jai Hyun Kwak (POSCO, South Korea) gave a talk on the development of highly formable Giga strength steels by Q&P processing at POSCO. Exciting presentations on various aspects of quenched and partitioned steels were made by researchers from other leading universities and research organizations, such as TU Delft (The Netherlands), University of Gent (Belgium), Max Planck Institute for Iron Research (Germany), University of Oulu (Finland), SWEREA KIMAB AB (Sweden), etc. The organizers thank all the presenters and attendees for participation in the Symposium and hope to meet again at the next MSE Congress in Darmstadt.

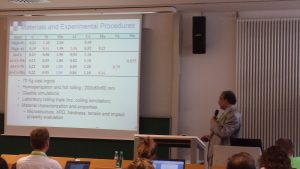

Pictures below (from left to right and top to bottom) show Dr. Stefan Van Bohemen (Tata Steel, The Netherlands), Prof. Emmanuel De Moor (Colorado School of Mines, USA), Dr. Irene De Diego Calderon (Arcelor Mittal Metz, France), Dr. Dorin De Knijf (Arcelor Mittal Gent, Belgium), Dr. Zhuangming Li (Max Planck Institute for Iron Research, Germany), Prof. Roumen Petrov (University of Gent, Belgium), Dr. Bij-Na Kim Lee (TU Delft, The Netherlands), Bernd Linke (ThyssenKrupp Steel Europe AG, Germany), Dr. Jai-Hyun Kwak (POSCO, South Korea), Prof. Mahesh Somani (University of Oulu, Finland), Dr. Alfonso Navarro-Lopez (TU Delft, The Netherlands), Dr. David Martin (SWEREA KIMAB AB, Sweden), Dr. Carola Alonso de Celada Casero (TU Delft, The Netherlands) and a group photo during the workshop at the MSE 2016 Congress.

Recent Comments